Guascor genuine, OEM and aftermarket parts for FGLD, SFGLD and HGMI engines.

Design, supply and manufacturing of energy solutions

GUASCOR POWER has evolved from the company GUASCOR S.A., which has been designing and manufacturing diesel and gas engines and energy systems since 1966..

In the world of Cogeneration - Generation systems, GUASCOR POWER is able to provide energy equipment and solutions for very different applications. We can also tailor our products to our customers' needs.

GUASCOR POWER's worldwide network of distributors provides quick and effective technical assistance and spare parts service.

All of this takes place within the scope of our commitment to quality, health and safety and the environment, as certified by ISO 9001 for quality management, ISO 14001 for environmental issues, and OHSAS 18001 for safety and occupational risk prevention.

Product range :

Liquid fuel engines

Engines using liquid fuels (diesel, bio-diesel) with a power output up to 1.730 HP, with a robust design, reliable operation and low operational costs. |  |

|---|

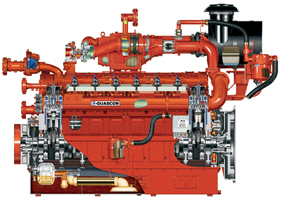

Gas Engines

Engines using gas fuels (natural gas, biogas, syngas, LPG, LNG, mine gas, dwell gas) with a high electrical efficiency, flexible operation and power outputs up to 1.200 kWe |  |

|---|

Dual fuel engines

Engines that combine the advantages of the liquid and gas fired engines, offering a very high operational flexibility, high reliability and a robust design |  |

|---|

Engines

Latest technology

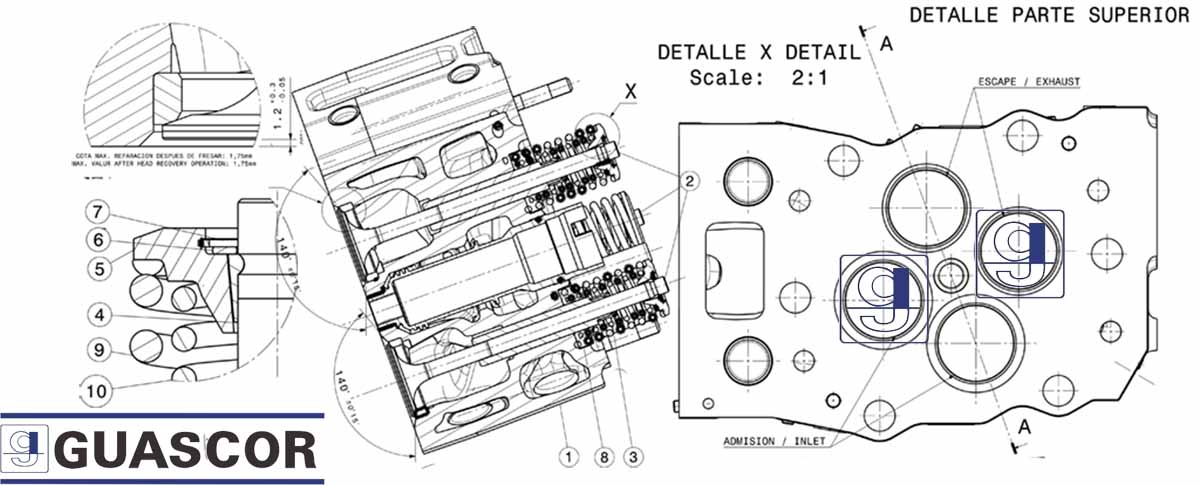

Guascor Power engines are four-stroke, direct injection, turbocharged, turbocharged-after cooled engines with four valves per cylinder.

Thanks to the application of the latest technologies in supercharging and fuel injection, it is possible to obtain more power while reducing consumption and the temperature in the combustion chamber.

Longer duration of the engine

The new designs for pistons and cylinder-heads and liner cooling systems guarantee the thermodynamic balance that results in less wear and longer duration of the engine components.

High quality materials and components

Piston tightness is provided by three rings, with a minimum of friction and at very low oil consumption. The materials and components used are A-quality and have passed hard stress tests and trials before their acceptance.

Quality control

Over 90% of the parts of the different models are interchangeable. This allows larger production runs, improved quality controls and a better service of spares.